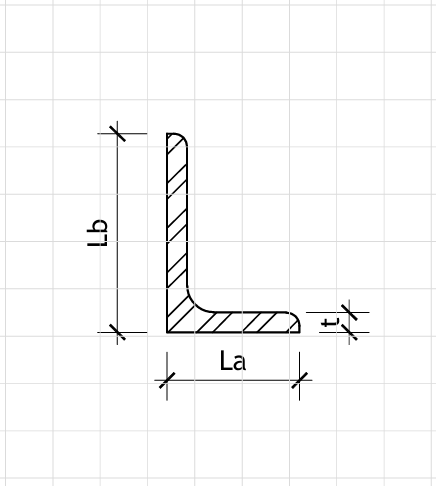

Section Dimensions (mm)

La = mm Length of leg a

Lb = mm Length of leg b

t = mm Thickness

Figure 1: Geometry

L-Section Dimensions

Material Properties (MPa)

fy = MPa Yield strength

fu = MPa Ultimate tensile strength

G = MPa Shear modulus

E = MPa Elastic modulus

Material Factors

γm0 = Material factor for cross-section resistance

γm1 = Material factor for buckling resistance

Applied Loads

Ned = kN Axial force (compression is positive)

Med,x = kNm Moment about major axis

Med,y = kNm Moment about minor axis

Ved,x = kN Shear force parallel to leg b

Ved,y = kN Shear force parallel to leg a

Lbuckling = mm Buckling length

Ag = (La + Lb − t) · t = 1900 mm² Gross area

Av,x = Lb · t = 1000 mm² Shear area for Ved,x

Av,y = La · t = 1000 mm² Shear area for Ved,y

Zpl,x = 10000 mm³ Plastic modulus (major axis)

Zpl,y = 10000 mm³ Plastic modulus (minor axis)

Axial Compression Check

Nc,Rd = fy · Ag / γm0 = 362.73 kN

Axial utilization: Utilaxial = 0.634

Shear Check

τy = fy / √3 = 121.24 MPa

Vpl,Rd,x = Av,x · τy / γm0 = 110.22 kN

Vpl,Rd,y = Av,y · τy / γm0 = 110.22 kN

Shear utilization (x): Utilshear,x = 0.000

Shear utilization (y): Utilshear,y = 0.000

Max shear utilization: Utilshear,max = 0.000

Bending Check

Mc,Rd,x = Zpl,x · fy / γm0 = 1.91 kNm

Mc,Rd,y = Zpl,y · fy / γm0 = 1.91 kNm

Bending utilization (x): Utilbend,x = 0.000

Bending utilization (y): Utilbend,y = 0.000

Combined bending utilization: Utilbend,combined = 0.000

Combined Forces Check (Simplified)

Combined utilization (axial + bending): Utilcombined = 0.634